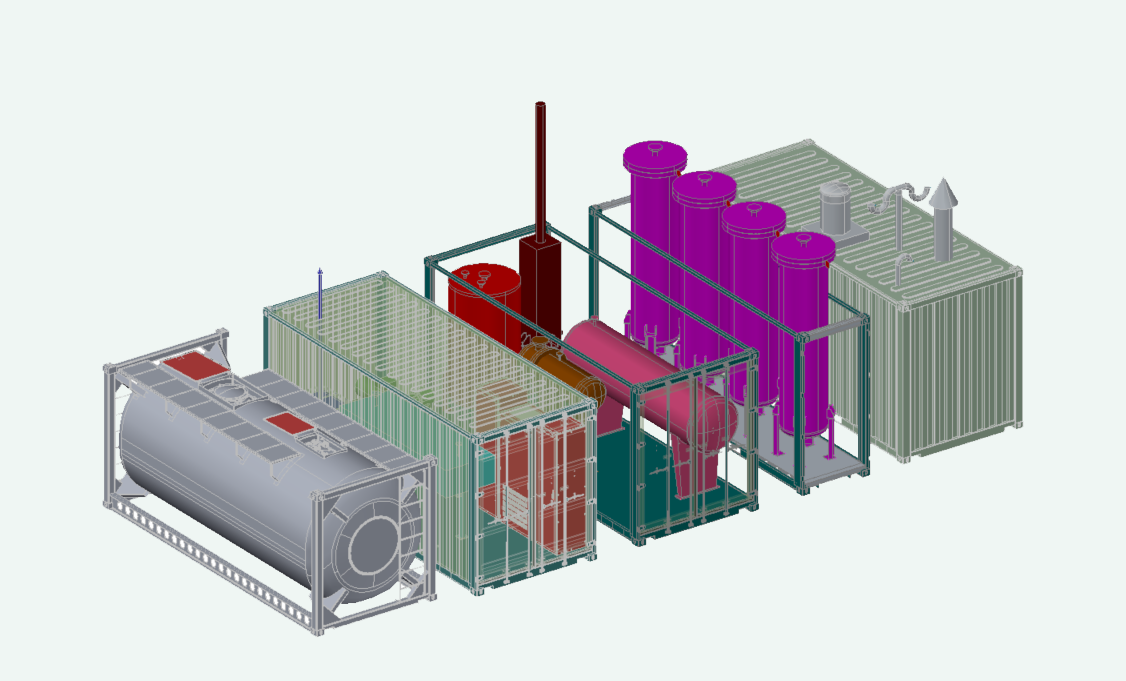

Schiedam, June 7, 2023 – Proton Ventures is awarded a feasibility study contract by Port of Rotterdam for the Scoping and Conceptual Design of an Ammonia Export terminal in Oakajee, Western Australia. 3 Million tons of ammonia per year is expected to be exported by 2030 to Port of Rotterdam via this future ammonia hub. […]

Proton Ventures is invited by VOTOB, The Dutch Association of Tank Storage Companies, to take part in the working group that will revise the PGS-12. The 4-chair workgroup, existing of delegates from Vopak, OCI, Yara International and Proton Ventures, will collectively improve the PGS-12. The import of large quantities of hydrogen in the form of […]

Proton Ventures is now an Associated Partner of Dii Desert Energy and a Member of the MENA Hydrogen Alliance. As key player in the ammonia infrastructure, Proton Ventures is always looking for new partnerships and expanding collaborations throughout the value chain. By partnering with Dii Desert Energy we hope to accelerate the energy transition not […]

Schiedam, 6 March 2023 – Proton Ventures BV (“Proton”) is awarded a Scoping & Feasibility study and a subsequent Front-End Engineering Design (FEED) project by the Dutch Vesta Terminals B.V. (“Vesta”) for re-purposing of two 30.000m³ ammonia tanks in Vlissingen, NL. Earlier last fall, Uniper Global Commodities SE and Vesta signed a Memorandum of Understanding […]

On Tuesday February 14th, visiting Dutch Minister for Foreign Trade and Development Cooperation, Mrs. Liesje Schreinemacher, witnessed the first steps towards a strategic energy corridor between The Netherlands and Brazil. In the presence of the Minister, the Dutch consortium Transhydrogen Alliance and its Brazilian partners Casa dos Ventos Energias Renováveis and Comerc Energia signed an MoU outlining […]

São Paulo, 2nd February 2023. Casa dos Ventos, a renewable energy company, and Comerc Eficiência, an energy efficiency company of the Comerc Energia Group, signed a partnership with the TransHydrogen Alliance (THA), whose objective is to create new supply chains for the energy transition of European countries. The purpose of the agreement is to enable […]

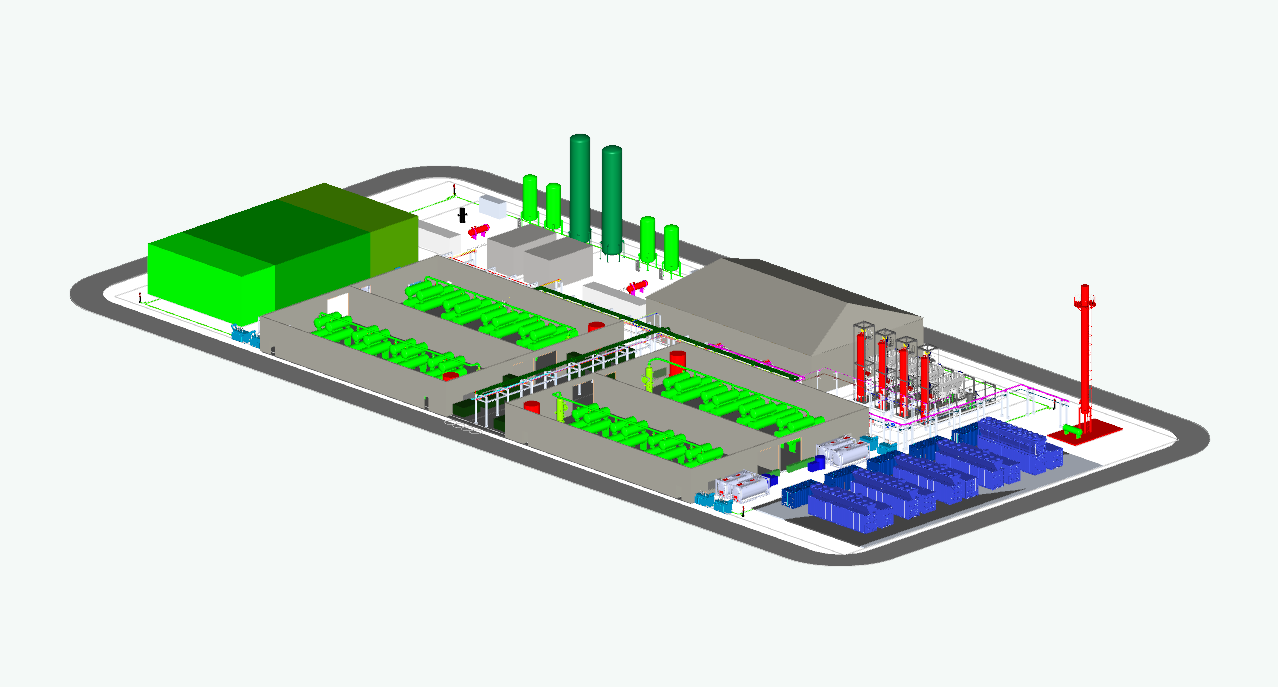

Proton Ventures and Fichtner are conducting a feasibility study for a multinational energy corporation for green hydrogen/ammonia production facilities at various locations throughout the world. The feasibility study will define the feasibility of a green ammonia production plant in Southern Europe, as well as explore other locations in South America and Africa. The green ammonia […]

January 25th Energy Storage NL (ESNL) presented the National Energy Storage Action Plan to Climate and Energy Minister Rob Jetten. The sector organization is a partner of the entrepreneurs’ organization for the technology industry FME. With this action plan, ESNL puts on the agenda the need to accelerate the energy transition through the use of […]

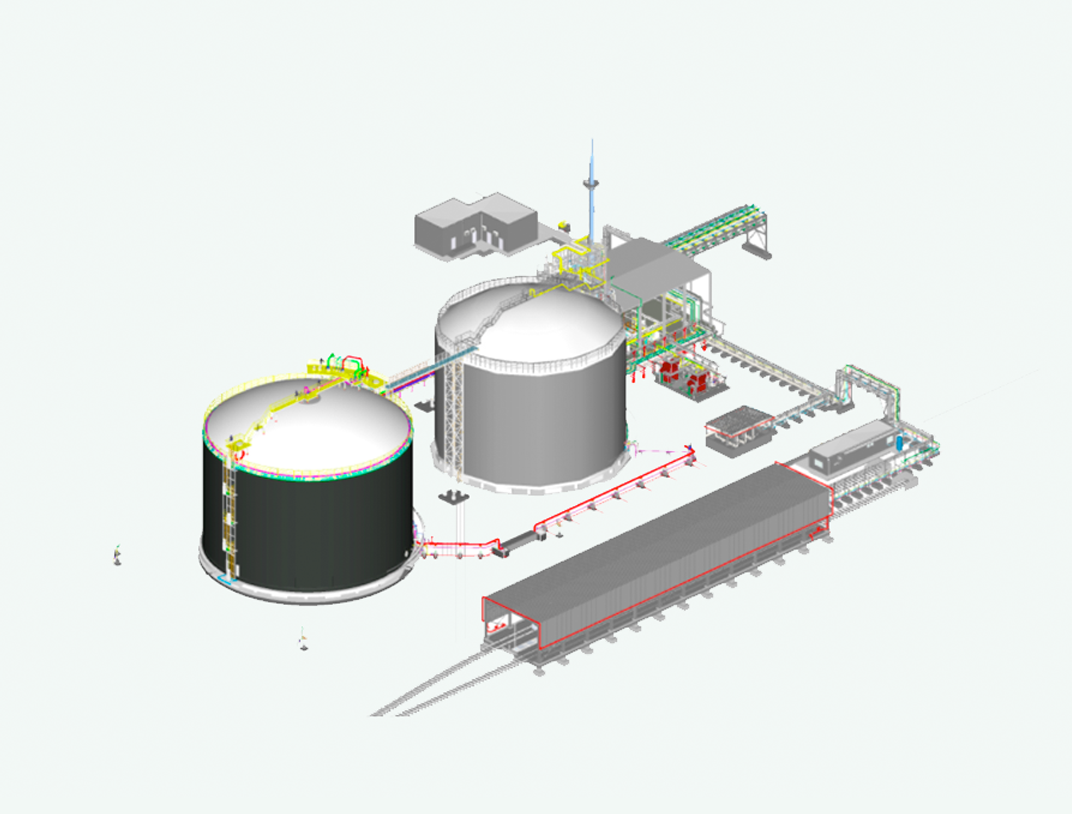

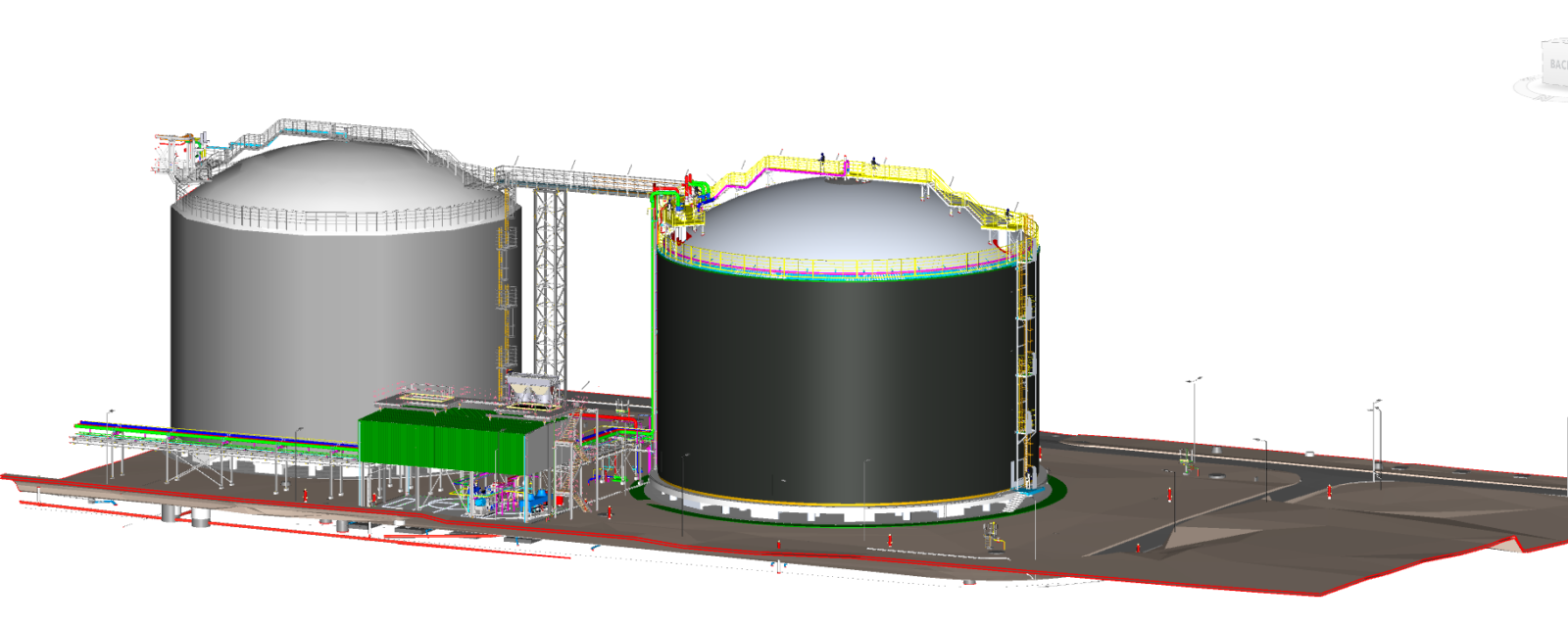

Morocco, 21th December 2022– Proton Ventures and its consortium partners Société Chérifienne de Matériel Industriel et Ferroviaire (SCIF) and Engineering &Group IPS are awarded a turnkey contract by Office Chérifien des Phosphates (OCP Group) to design and build two refrigerated ammonia storage tanks in the Industrial Complex Jorf Lasfar in Morocco. The project, which kicked […]

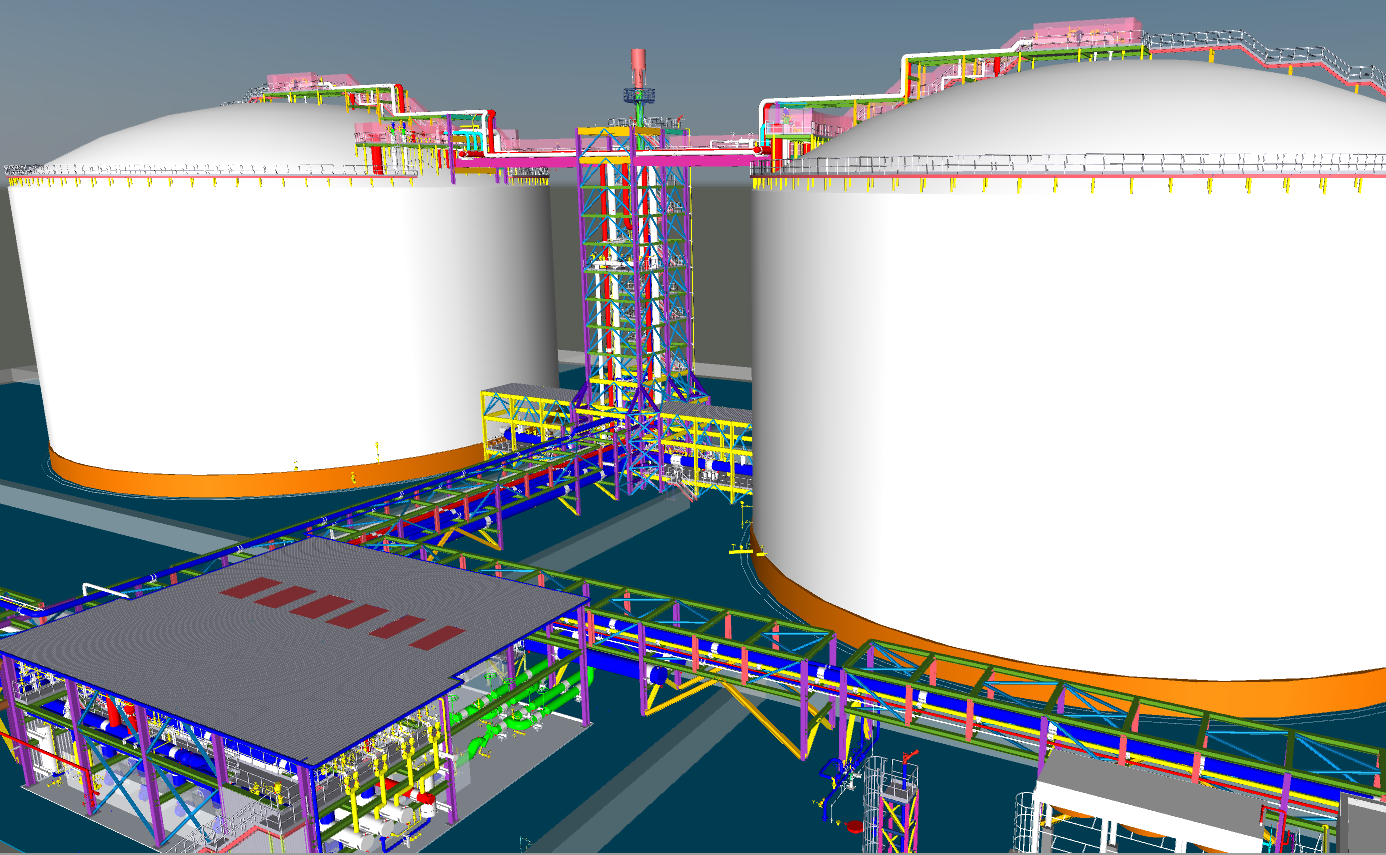

Proton Ventures is awarded a FEED+ engineering package (Basic Engineering plus partial Detailed Engineering) for a new ammonia export terminal by the biggest Oil, Gas & Chemicals company in UAE. The project, which kicked off in January 2022, will be finalized in the third quarter of 2022 and boasts the biggest ammonia tanks ever built […]