Empowering green ammonia

and energy solutions

Ammonia production

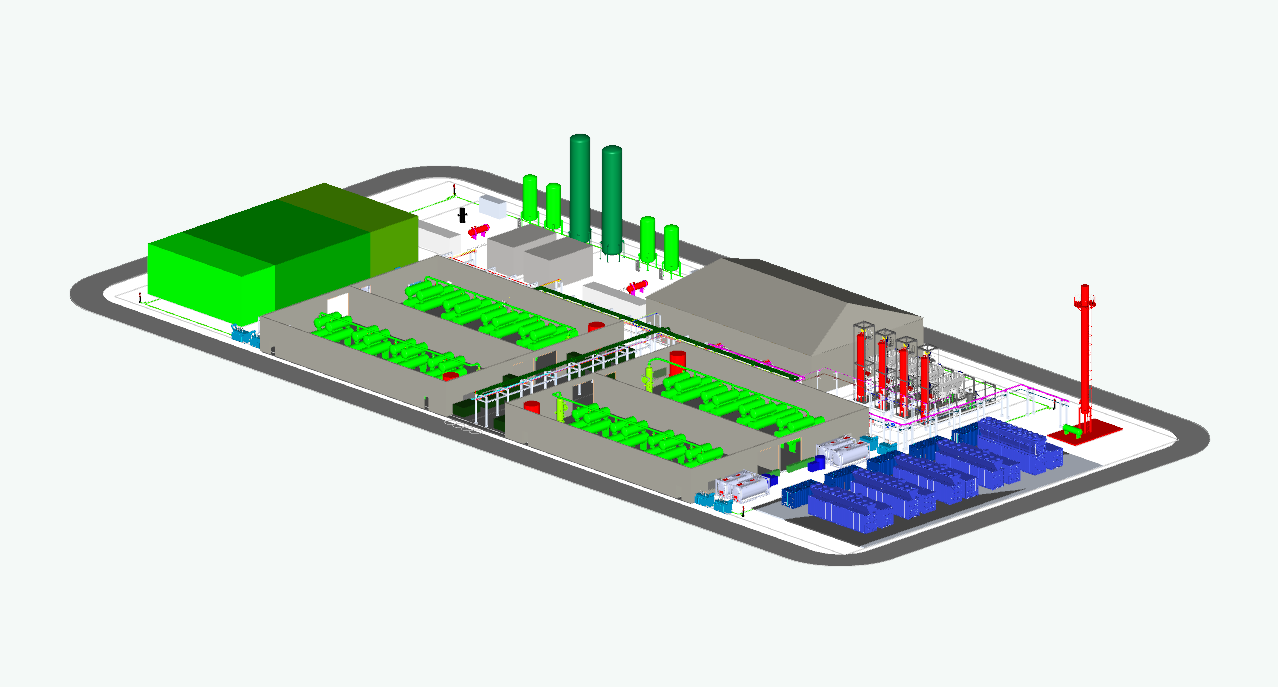

Proton Ventures performed a Front-End Engineering & Design (FEED) study for a renewable ammonia plant in close collaboration with Casale S.A. from Switzerland. This is the smallest ammonia module (NFuel System) in Proton Ventures’ product portfolio.

Proton Ventures developed a conceptual design for a new 300 MTD modular ammonia plant including a class 3 AACE engineering cost estimate. The Ammonia Plant offers maximum flexibility, allowing for future implementation of electrolysers in order to produce green ammonia.

Proton ventures developed a brownfield Basic Engineering (BEP+) design for an ammonia production facility producing 48 MTD of ammonia per year. Hydrogen obtained through a chloro alkaline process, nitrogen and utility streams would be provided by the client (a utility provider) for the production of ammonia.

Liquefied storage & handling

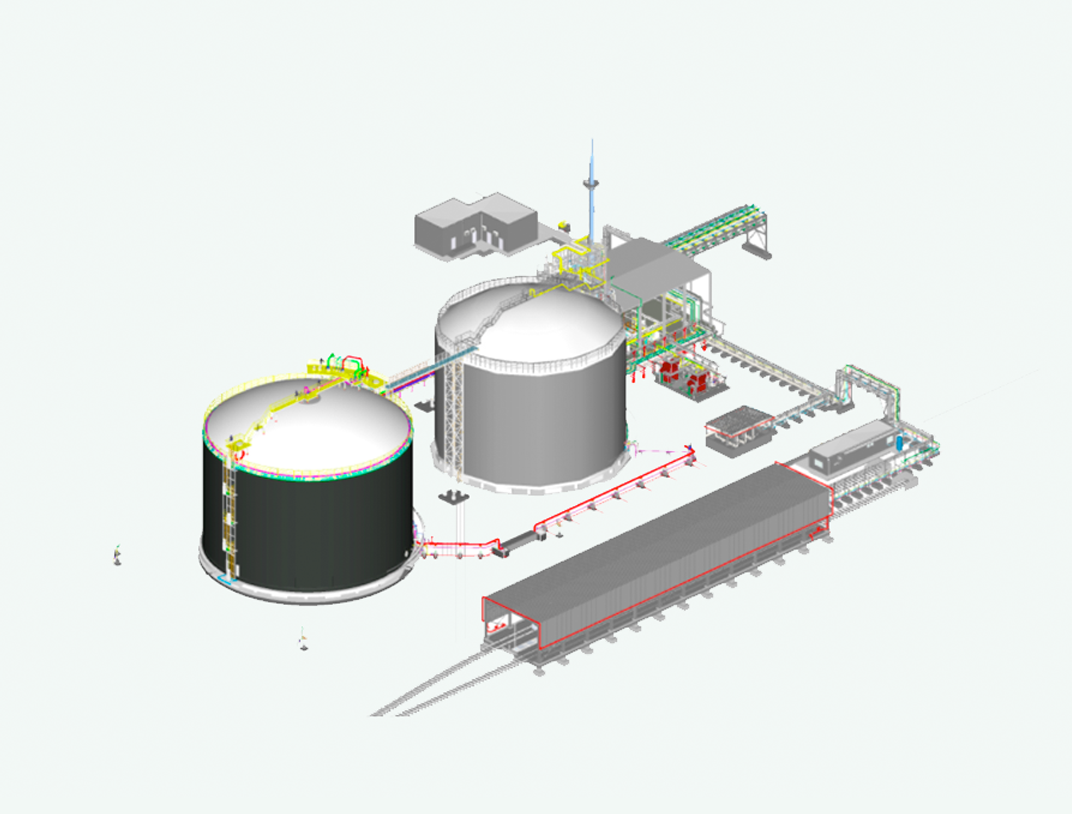

Estonia

Proton Ventures handled the basic engineering (process, mechanical, electrical, instrumentation & control, piping) for the largest ammonia storage and handling facility in Europe, comprising two refrigerated ammonia tanks (30,000 metric ton capacity, Europe’s largest storage tanks), four UAN tanks (20,000 metric ton capacity), marine loading arm facility, main & holding compressor skid, railroad freight car loading facility & utilities.

Bulgaria

In 2013, Proton Ventures performed the basic and detailed engineering (process, mechanical, electrical, instrumentation & control, piping) for the ammonia terminal comprising a 10,000 metric ton storage tank, marine loading arm facility, holding compressor skid, railroad freight car loading facility, scrubber system & utilities

Thanks to this successful collaboration, Proton Ventures was awarded a new project in 2019 to realise a second tank (12,500 ton tank) with associated peripherals. The second tank is already built and the project will be completed before the end of 2022.

DENOX and N2O removal Kavala

In collaboration with Haldor Topsoe, Proton Ventures realised the successful startup of the first TertiNOx™ catalyst reference at Kavala Fertilizers, one of the largest nitric acid producers in Greece. The plant has already exceeded its design conversion with N₂O emissions below 10 ppm and low ammonia slip, and has practically eliminated NOx emissions.

At the current performance level, Kavala Fertilizers’ nitric acid unit in Greece will reduce its greenhouse gas emission by more than 30,000 tonnes of CO2 equivalents per year. This leads not only to more sustainable operation of the plant but also to significant cost savings as a consequence of lower impeded carbon taxes.

Other references

Environmental impact study

Ammonia safety study

An important part of the environmental impact studies is the QRA (Quantitative Risk Analysis) which provides among others contour diagrams as shown in the figure. Proton Ventures executed and delivered said studies and cooperates where needed with its partners for this type of work.

Studies (examples)

International

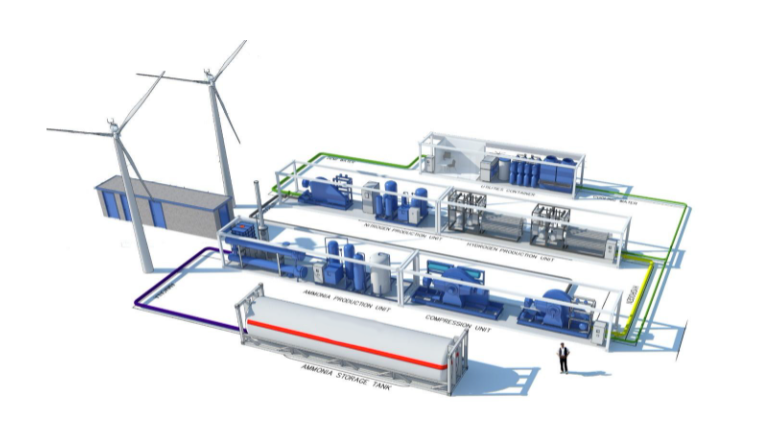

Project Development Feasibility study & Location analysis for various (80,000, 500,000 & 1,000,000 ton/year) green ammonia plant configurations, including export & import terminals, Ammonia transportation & (partial) NH3 decomposition (cracking toward hydrogen)

USA

Techno-Economical Feasibility study of a 80,000 ton/year green ammonia plant based on 100 MW electrolysis.

Techno-Economical Feasibility study of a 80,000 ton/year (4 ammonia synthesis loops of 20,000 ton/year capacity) modular ammonia plant.

Netherlands

Techno-Economical Feasibility study of an offshore medium scale green ammonia plant based on electrolysis.

Canada

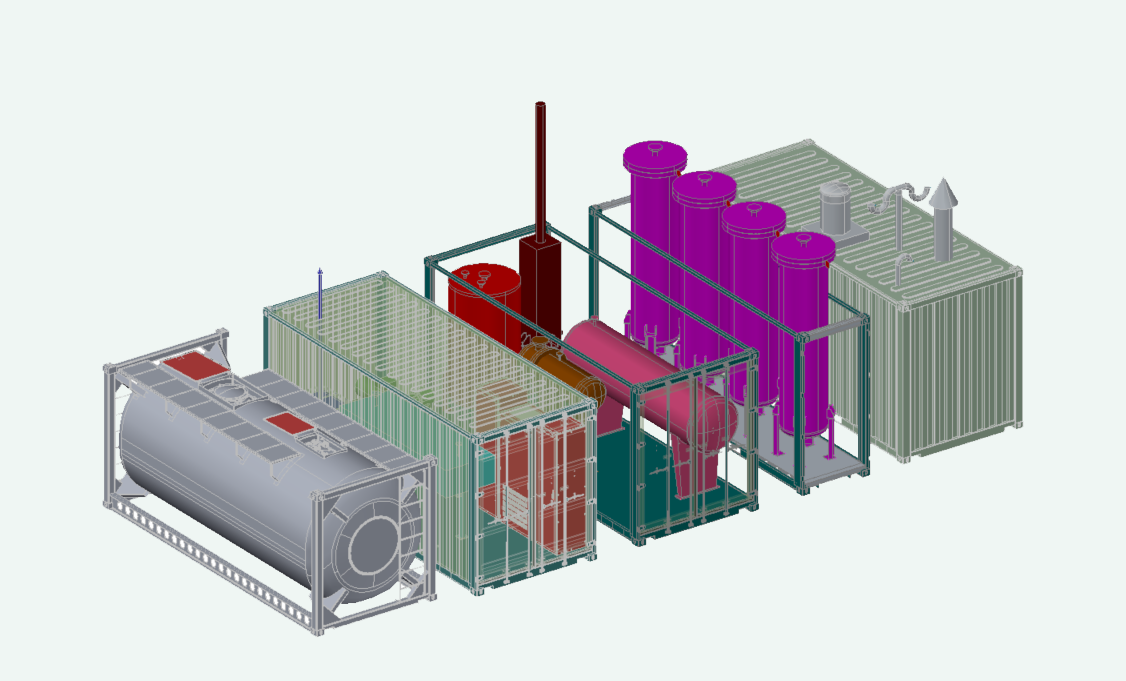

Front-End Engineering & Design (FEED) of a 3 metric ton per day modular ammonia plant with electrolysis in Quebec, Canada.

International

Techno-Economical Feasibility study for water injection system and an onsite aqueous ammonia unit.

EPC(M) & Engineering (examples)

Estonia

Basic engineering, Detailed engineering support, construction supervision and start-up and commissioning of a 60,000 metric ton capacity anhydrous ammonia and 60,000 metric ton capacity UAN tank storage facility in Estonia.

Bulgaria

Basic engineering, Detailed engineering, Purchasing of main equipment, site construction supervision and commissioning of a 10,000 metric ton capacity ammonia storage facility in Bulgaria incl. Ship Unloading and Railcar Loading at 4x Loading Bays.

The Netherlands

Revamp, start up and operations of a 30,000 metric ton anhydrous ammonia storage facility & utilities in Rotterdam.

Poland

Engineering contractor for the expansion program for a LNG terminal in Poland; Railcar facility design for the loading of LNG into rail tankers and ISO containers at 12x Loading Bays with Dynamic Weighing bridge

The Netherlands

EPC contractor for the new HCL storage tanks and handling

Greece

EPC contractor for de-NOx and N2O reduction SCR System for a Nitric Acid plant.

The Netherlands

Total Engineering Services for the Battolyser project